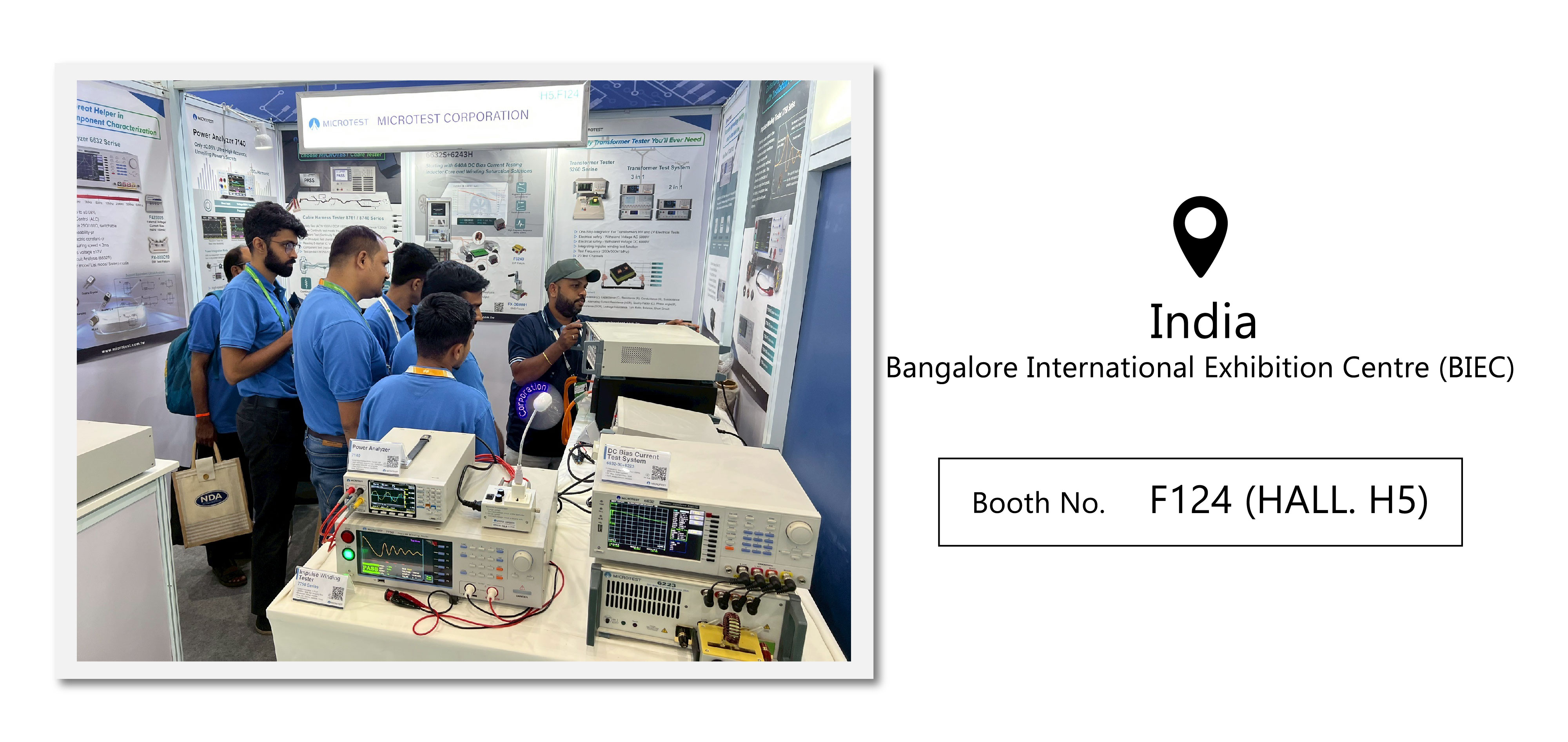

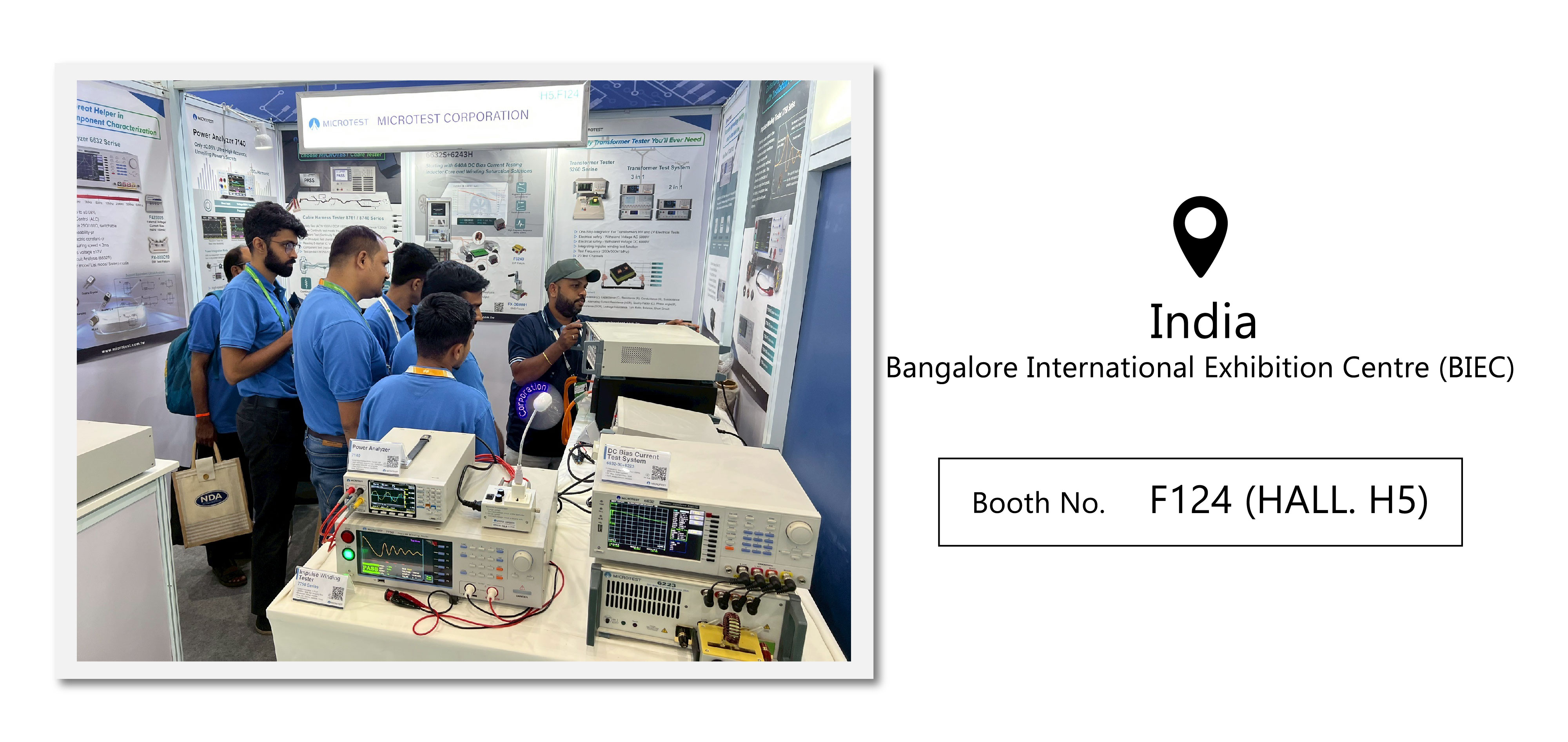

Post-Show Review | MICROTEST Insights from electronica India 2025

At electronica India 2025, MICROTEST clearly observed that India’s electronics industry is accelerating its transition from assembly-based manufacturing to advanced core components and high-performance test technologies. In recent years, the Indian government’s Electronics Component Manufacturing Scheme (ECMS) has provided substantial subsidies and incentives aimed at strengthening local component manufacturing capabilities and enhancing global competitiveness. Meanwhile, the inductor market size is projected to reach approximately US$200.6 million by 2033.

At this exhibition, MICROTEST showcased its high-power inductor saturation current and temperature rise current measurement solutions, which drew significant attention and inquiries from attendees. This reflects the rapidly growing demand in EV and renewable energy applications for validating the saturation characteristics of high-power inductors.

In high-power applications such as EV drive systems and renewable energy conversion equipment, saturation current and temperature rise current are critical parameters that determine inductor reliability and performance. Saturation current represents the maximum current an inductor core can handle before reaching its magnetic flux density limit. Once this limit is exceeded, inductance decreases sharply, causing current waveform distortion, circuit resonance failure, and even power device overload. Temperature rise current, on the other hand, indicates the inductor’s thermal behavior under real operating conditions, reflecting the heat generated by copper and core losses. Excessive heat not only accelerates insulation aging but also degrades magnetic material performance, ultimately impacting system efficiency and lifetime. For EVs, these two parameters directly affect safety and driving range under high-voltage, high-current environments. In renewable energy systems, they are decisive for the stability and long-term reliability of inverters and energy conversion units.

Therefore, neglecting saturation current and temperature rise current specifications during inductor design and selection can lead to performance degradation and even systemic failures. For high-power applications, rigorous evaluation and validation of these parameters have become non-negotiable requirements in inductor design. By addressing this demand, MICROTEST provides a unique global solution for high-power inductor testing under DC bias conditions, offering the world’s only system capable of integrating up to 640A DC Bias Current Source with an Impedance Analyzer. This enables validation of inductor frequency response under high current (100Hz–10MHz / up to 640A), ensuring true performance verification of high-power inductors.

MICROTEST will continue to focus on innovations in high-power inductor testing technologies, helping engineers in EV and renewable energy sectors ensure system performance and reliability. Through comprehensive test solutions, MICROTEST is setting a new benchmark for high-power component validation.